WhatsApp)

WhatsApp)

From one simple but inspired solution to a misalignment problem in a textile mill in Sweden, and fifteen employees in 1907, SKF has grown to become a

critical speed of ball mill – Ore equipment: ore crusher, ore . Ball mill critical speed, ball mill efficiency. What is the ball mill critical speed and how to ...

critical speed of a ball mill and ball size – Grinding Mill . Posted at: July 30, 2012. Ball mill – Wikipedia, the free encyclopedia The critical speed can be ...

Ballend Hex Wrenches (110413) These are so handy that I should have added them to this page years ago. (but I''ve been busy!) I have an SAE and a metric set made by ...

Running the correct PROMAX solid carbide end mills at the proper speeds and feeds is critical to obtaining the best production times and tool life.

Sep 09, 2013· Home Inspection Services in Chicago area. Call us at for a free quote and have a home inspector stop by your future property. The Inspection ...

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

Pictures of the Taig Lathe, Mill Other Tools and Accessories . Here are pictures of the Taig Micro Lathe and Taig Milling Machine, pictures of my machines and other ...

Mill Speed Critical Speed. Mill Speed. No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

Schaeffler Group Industrial 1 Contents Product Description 2 Ball Nuts 3 Load Rating And Life 4 Critical Speed And Buckling Load 5 Ordering Designations 6

Building a BrooksStent Cutter Grinder. Last Modified: 06 May 2016 01:20 MST Click to Enlarge . I eventually returned to my old notion of building a BrooksStent ...

Critical rotation speed of dry ballmill was studied by experiments and by numerical simulation using Discrete Element Method (DEM). The results carried out by both ...

In this article: Axis control technology gives one sailboat an edge in speed and stability ACVbased control system precisely adjusts keel position in a single ...

From textile machinery to vehicles, there is always a need for bearings. Let us locate the ball bearings you need from qualified and trusted manufacturers!

Tips for Getting the Best CNC Milling or Turning Surface Finish. CNC Milling Feeds and Speeds Cookbook

Fitzpatrick''s lab grinding mill for size reduction offers superior accuracy scalability. Discover how our equipment can help minimize product losses!

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

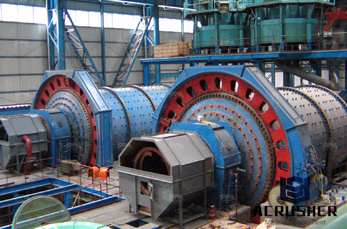

The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed. Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns.

Pentair 011056 IntelliFlo VSF, 3HP Variable Speed and Flo Pool Pump | TC Pool Equipment Co. Best Brands For Less! The energy saving 011056 IntelliFlo VSF ...

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm.

Since this site was first put on the web in 1999, its popularity has grown tremendously. If the total quantity of material on this site is to continue to grow,

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

Langhorne Players is a 501(c)3 nonprofit, all volunteer community theater in Bucks County, Pennsylvania that produces thoughtprovoking plays meant to engender after ...

Ball mills have been successfully run at speeds between 60 and 90 percent of critical speed, but most mills operate at speeds between 65 and 79 percent of critical speed. Rod mills speed should be limited to a maximum of 70% of critical speed and preferably should be in the 60 to 68 percent critical speed range.

WhatsApp)

WhatsApp)