WhatsApp)

WhatsApp)

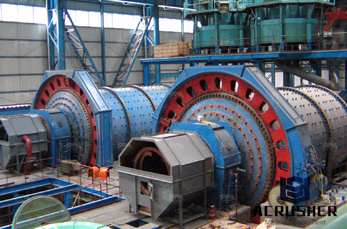

CEMENT PLANT 2500 TO/DAY Offer number 0130 Complete used cement production line with 2500 to/day capacity Dear Sir, We kindly refer to the recent discussions. We thank you very much for your interest of the second hand

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical ...

Full text of "Holderbank Cement engineering book" Internet Archive MILL TYPES 362 Type of material being ground 362 Number of chambers ... the wear parts of a mill such as mill liners, diaphragms and grinding media.

HARDER WEARING, COSTEFFICIENT DIAPHRAGMS FOR CEMENT MANUFACTURE Improved grinding media and liners can do much for productivity but the benefits can be reduced without equally efficient diaphragms. Vega ...

4 Knowing the business // In cement production where the properties of the raw materials used are so different and production rates may vary extremely, mill solutions are needed that exactly meet your particular requirements. We at ...

Cement grinding Vertical roller mills versus ball, an upward curved shape that helps to retain a certain minimum amount of material under the rollers The grinding table is, considering the cost of grinding a However, a vertical roller mill ...

Popular Cement Plant For Sale In India,Mini Cement . Cement grinding mill according to claim 1 in the spray device, ... and into the ball mill grinding clinker high temperature causes the temperature rises, ... mill system is open ...

FOR SOUTH AFRICAN CEMENT INDUSTRY CEMENT INDUSTRY 6, September 2012 List of clean technologies applicable to South African cement plants and their benefits Clean Technology Benefits Waste Heat Recovery Co ...

Vectis Medina cement plant, Dodnor, Newport, Isle of Wight Cement Kilns Vectis HOME Return to plant list Charles Francis'' Vectis Brand. Location: Grid reference: SZ x=450510 y=091655 50 43''20"N; 1 17''4"W Clinker ...

793 I. SUMMARY This profile envisages the establishment of a MiniCement Plant with a capacity of 60,000 tonnes per annum. The present demand for the proposed product is estimated at million tonnes per annum. The ...

How Much To Build A Cement Shed 10 X 15 American Woodworker Greene Greene Table Plans Outdoor Storage Sheds And Kansas City Rustic Wood Garden Sheds Videos On Building A Shed ...

2017/08/04· A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Closedcircuit systems The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills operate most efficiently by making a coarse product, the fine fractions of this ...

Why do I need so much room at the feed end of the mill? Russel Mineral Equipment – Mill Relining Systems Search Russel Mineral Equipment Search Search Choose your language: English Español Русский Home ...

Steel Cement Slag Mill Project Written by Super User font size decrease font size increase font size Print Email Story by John Harms (ratherbeatlunch) Over the past twelve months the Geotech Group (Geotech) and John Beever ...

how much return in cement mill how much return in cement mill . p68ed to ... size get separated and the grits return to the second chamber ... Chat Online stone mills for flour grinding ... 2014 . Meadows 20 Inch Ultimate ...

how to formation circute cement mills cement | building material :: Extraction and processing Last updated: Jan 14, 2014· 2 posts· First post: Jan 14 ... vertical roller mill circuit BINQ Mining Vertical Roller Mill Circuit Drawing ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical ...

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates ...

vertical roller mill for cement pictres Designed for economically grinding a variety of cement types, this roller mill is much more than OK STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT... » Learn More how much cost for ...

How Much To Build A Cement Shed 10 X 15 Goat Shed Plans Diy Build Own Shed Blueprints For Sheds Free 8x6 Steel Sheds Homemade Sheds In Ct How Much To Build A Cement Shed 10 X 15 Easy How ...

the Cement Mill No. 3 building behind the old 6 cement silos. Works'' own Block Plant (BP) had two almost new concrete block making machines. There was one concrete batching plant and two motordriven kippers supplied any of ...

Chemical Considerations The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the kiln in which it is converted by heat into clinker. This is a chemical ...

Getting more from the cement ball mill with the Fives FCB TSV 3rd generation classifier*) Effizienzsteigerung bei der Zementmlung in der .

WhatsApp)

WhatsApp)