WhatsApp)

WhatsApp)

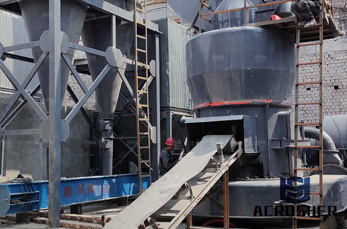

Vertical Roller Mill Working Principle Material through the feed tube fell on the center of vertical roller mill grinding plate, centrifugal force generated from the ...

· CENG Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. such as slag,cement coal,and so on.

· Process in vertical raw mill. Process in vertical raw mill. Skip navigation Sign in. Search. ... vertical roller mill working principle Duration: 2:54.

Raw Material Vertical Roller Mill. Our raw materials vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum.

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River .

How does vertical roller mill work? Vertical roller mill working principle is just like this: main motor rotates by designed power, and material falls onto millstone ...

Vertical Roller Mill Plants. Vertical roller mill is a kind of superfine grinding equipment, production and processing has been widely applied in foreign white non ...

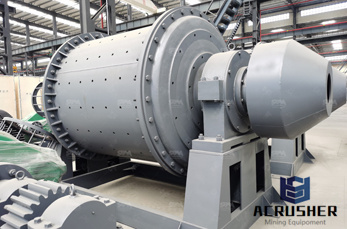

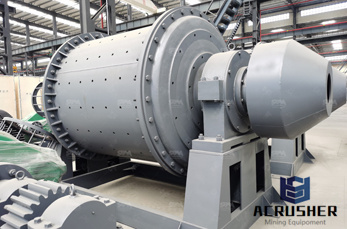

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

vertical roller mill small vertical mill working principle is manufactured from Shanghai Xuanshi,It is the main mineral processing solutions.

Slag vertical roller mill grinding roller pressure adjustment is made via an external spring, which must be based on the hardness of the material, size, water, feed ...

Crusher machine with perfect combination between crushing efficiency and operating cost. ... Vertical Roller Mill. In vertical roller mill working process, ...

By replacing ball mills with vertical or horizontal roller mills in raw material preparation, energy savings of 610 kWh/traw materials (depending on grindability of ...

Vertical mill are suitable for huge capacity producing, ... Working Principle of Vertical Roller Mill. The grinding disc is driving by motor through reducer.

4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying

Vertical Roller Mill worldsfittestman. Vertical roller mill working principle. Vertical roller mill is based on the working principle of a Raymond mill.

Vertical Roller Mill (VRM) 3 Sections Vertical Roller Mill (VRM) Details Vertical Roller Mill ... Working principle Material bed Feed material Max Particle ...

working principle of raymond mill and vertical roller mill Great Wall Heavy Industry is a professional manufacturer of mining machine for almost 20 years in China.

Vertical roller mill Manufacturer. Working principles of the Vertical Roller Mill: The motor dives the grinding table to turn through the speed reducer.

Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed ...

Vertical roller mill, roller separator, disc, compression devices, vertical speed reducer, motor, shell and other components. The separator is an important component ...

Vertical Roller Mill Working Principle. The disc to rotate by the reducer, so the material through the air lock feeder from the feed inlet fall at the center of the ...

Vertical roller mill feature and working principle. Vertical Roller Mill is my company based on the extensive use of advanced technology at home and abroad, and ...

Vertical raw mill is a type of industrial equipment used to crush or grind materials ... The biggest homemade raw material vertical roller mill. ... Working Principle.

Vertical Roller Mill Working Principle: Vertical Roller Mill use 2 to 4 grinding rollers close to the disc, as the speed of rotation of the material ground.

WhatsApp)

WhatsApp)