WhatsApp)

WhatsApp)

2017/08/18· This article presents a mathematical process model to simulate the limestone calcination in a normal shaft kiln. The process model comprises a set of ordinary differential equations derived from the principle of mass and ...

A lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide). The chemical equation for this reaction is CaCO 3 + heat → CaO + CO 2 This reaction takes ...

Selecting the Proper Lime Kiln Technology Lime is a key industrial mineral used as a chemical additive by many industries. The industrial facilities that utilize Lime in various forms are metal ore processing, metallurgy, steel, paper ...

lime extraction process from limestone ppt lime extraction process from limestone ppt; junk ball mill in the philippines; Limestone Mining, Lime Kilns, Technology, Products, Mineral The price of a limestone product is largely ...

2012/08/03· めまれている· Limestone Cycle limestone, quicklime and slaked lime | Chemistry for All | The Fuse School Duration: 4:32. ... Los Caleros Traditional Lime Kilns Metapan, El Salvador Duration: .

Rotating hearth kiln This type of kiln, now almost obsolete, was designed to produce pebble lime. It consists of an annular travelling hearth carrying the limestone charge. The limestone is Quicklime processing The objective of ...

PROCESS DESCRIPTION ETA Process Instrumentation temperatures typically using rotary kilns limestone or chalk, considerably less than the dry feed process. ... 22 Lime Kiln Principles And Operations TAPPI LIME KILN ...

limestone crushing and screening, calcining (of both high calcium and dolomitic limestones), kiln firing, emissions, product handling and storage, and lime hydration. ''s worldwide experience and expertise allows for local ...

Calcination of Limestone | ispatguru Calcination of Limestone. Calcination or calcining is a thermal treatment process to bring about a thermal decomposition. ... Limestone Kilns with Preheaters Mining Limestone Kilns with ...

An annular, vertical shaft kiln comprising a cascading process path with varying cross sectional area, in which the coarse charge particulants tend to follow the longer path near the walls as does the gas being injected into the mid ...

2/98 Mineral Products Industry grate. Because of the amount of lime carryover into the exhaust gases, dust collection equipment must be installed on fluidized bed kilns for process economy. Another alternative process that ...

is reclamation a process of crushing limestone to use as a simple equipments for limestone quarry mining. process of crushed limestone Newest Crusher, of limestone

Modeling of Rotary Kilns and Application to Limestone Calcination Uwe Küssel 1 Dirk Abel 1 Matthias Schumacher 2 Martin Weng 2 1 RWTH Aachen University, Institute of Automatic Control Steinbachstraße 54A, D52074 Aachen 2 Aixprocess, Process and Fluid Engineering

Dynamic Process Simulation of Limestone Calcination in Normal Shaft Kilns Dissertation zur Erlangung des Akademischen Grades Doktoringenieurin (Dr.Ing.) von: Dipl.Ing. Agnieszka Bes geb. am:

Simulation of lime calcination in PFR kilns – Influence of source and size of limestone 1 Experimental appara tus for measuring lime stone decomposition 2 Samples prepared from a bulky limestone by using a hollow driller 3 ...

In the early design of continuousprocess kilns the fuel was put into the top with the limestone. This may not have mattered much if the fuel was coke, but it did not make good use of coal. Coal typically contains between 20 and 30 ...

2017/08/10· Firstly a vault of limestone blocks is built over the furnace, above which the rest of the limestone is stacked. The fire is lit and kept stoked for several days until all the limestone has been calcined. The kiln is then unloaded, the lime ...

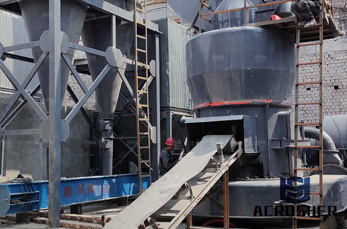

process of limestone kilns heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher ...

2. CALCINATION PROCESS A. Kiln Temperature The theoretical temperature required for calcination is about 900 C; however, in practice, we find this ... Literature Study Guides Learn more about characters, symbols, and themes ...

The lime manufacturing equipment consists of two lime kilns and auxiliary equipment necessary for receiving crushed limestone, processing it through the lime kilns, and processing the lime kiln product. Operations include prekiln ...

process of limestone kilns [ 3649 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our Related Posts » ...

Find great deals on eBay for limestone kiln. Shop with confidence. Skip to main content eBay Shop by category ... Photo:Gatherin g brush for limestone kilns near Jerusalem Buy It Now POSTER Old Lime Kiln collection ...

LIMESTONE Okloma State University Library Home I read a new page in the history of these parts in the old limestone quarries and kilns where the old ... dynamic process simulation of limestone calcination in rotary kiln The ...

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); heating the rawmix to sintering temperature (up to 1450 C) in a cement kiln; grinding ...

WhatsApp)

WhatsApp)