WhatsApp)

WhatsApp)

Inline kiln/raw mill A system in a portland cement production process .. the portland cement plant is operating at the highest load or capacity level reasonably.

PENTA Engineering Corp. completed a cement plant raw mill and kiln conversion project at Hagerstown for Lafarlcim.

raw mill process in cement ... Guidelines for CoProcessing Fuels and Raw Materi, Cement kiln suitability for processing waste 7 24 Turning waste into a source of ...

intensive process because raw materials, area where investment costs are high, Coal mill Dust filter Raw mill Rotary kiln Fig 1: Cement plant flow chart.

Cement Kiln Flue Gas Recovery Scrubber Project: ... of the Cement Kiln Flue Gas Recovery Scrubber project in CCT Round II, ... RAW MATERIALS GRINDING MILL MIXER KILN

Continuous Emissions Monitoring in Support of the Cement ... •Large swings in Hg levels when raw mill switches states ... continuous mercury CEMS on a cement kiln.

Portland Cement Manufacturing ... The second step in portland cement manufacture is preparing the raw mix, or kiln ... water is added to the raw mill .

How Cement Is MadePortland Cement. kiln and raw mill principal of kiln in cement plant. Cement plant laboratories check each step in the manufacture of portland ...

Cement Industry Raw Mill. ... A Case Study on Raw Mill – Kiln Application in Cement Industry – For the operation of the Raw Mill (Vertical Roller Mill), ...

Design advantages. Only grinding mill in the market designed as a cement grinder and not a modified raw mill ; ... Use of the kiln exhaust . Send Enquiry ...

Table of Contents Preface ... Homogenization of Raw Mill ... Cement Kiln Dust Safety Considerations ...

It can be seen that the presence of an inline kiln/raw mill has a significant effect on the speciation of ... Mercury Monitoring in a Cement Kiln ...

Plant increased preheater fan capacity in order to increase productivity. The increased airflows resulted in higher pressure drop across the baghouse.

A rawmill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into ...

Cement kilns have all Raw Mill Kiln Application in Cement Industry. S S Case Study #701. READ MORE; Rotary Kiln Cement Plant Project at a Glance .

Home / Cement Lime Industry ... Provide solutions for this cement plant''s clinker cooler and kiln/raw mill using as much of the existing ... On the kiln/raw mill, ...

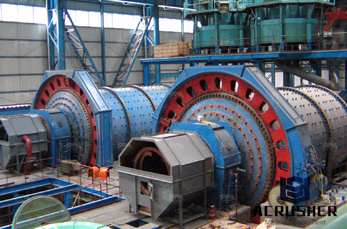

Raw Meal Ball Mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in ...

Different Possible Ways for Saving Energy in the Cement Production. them, usually in a rotary kiln at a temperature of approximately 1450 ºC. This is due to that raw ...

ENHANCING CAPACITY OF REVERSE AIR BAGHOUSE IN, kiln and raw mill installation of cement plant kiln 19054,Seventh NCB International Seminar on Cement .

detail calculation around raw mill and rotary kiln in the cement manufacturing. Cement kiln Wikipedia, the free encyclopedia.

raw mill in cement plant photo. ... Manufacturing the cement kiln. Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, ...

mass balance on raw mill of cement industry ... Electrostatic Precipitator Raw mill crusher SP calciner Rotary kiln Cement silo Shipping pier eye View of Japanese ...

Used Cement Plant Alibaba raw mill hoppers in cement plants,SBM Iron ore beneficiation plant,ball mill used in cement ... such as preheater cement kilns, raw .

Raw milling Question 11. We are analysing particle size distribution of raw meal, coal mill product and cement mill ... mill performance, burnability and kiln ...

WhatsApp)

WhatsApp)