WhatsApp)

WhatsApp)

Grinding is a finishing process used to improve surface finish, abrade hard materials, and tighten the tolerance on flat and cylindrical surfaces by removing a small ...

While the stepbystep process for polishing concrete varies from company to company, the overall process is the same. Get step by step info here.

The Backgrinding Process . To improve the productivity of an operation, a multistep grinding operation is generally performed.

process of the polishing work ... and step up toward finer one to make the shape ... ( grinding the stone surface often with another stone to keep its surface even ...

The first step operates with a pulsed Nd:YAG laser, the wavelength of which ... The DBG process requires a back grinding tape that has the following attributes.

The centerless grinding process is ideal for finishing small cylindrical metal parts that require a tight tolerance and highvolume production.

Throughout the grinding wheel''s history, ... but today materials that vaporize during the firing step of ... Stuart C. Modern Grinding Process ...

for purchasing the WORK SHARP tool grinding and ... This step is critical ... This process may take some time (3–10 minutes) ...

Camshaft Grinding Process: The first step is to inspect the camshaft to see if it needs any welding or other repairs. After the repairs are made, ...

Step Grinding. Step grinding is the process where multiple diameters are ground together, or one diameter at a time. ThruFeed Grinding. In thrufeed centerless ...

A fiber grinding process includes: contacting an end of the optical fiber with a grinding surface in such a manner that a central axis of the optical fiber at the end ...

About grinding and polishing ... This is normally the first step in the grinding process. Plane grinding ensures that the surfaces of all specimens are similar, ...

Optimizing The Grinding Process. ... optimized grinding represents a step toward competing in a global economy ... Shin''s work on the grinding process will ...

Grind Wax Process. Flattening. ... the grinding wheel is redressed for each step, and the structure is applied in a single pass for each stage. Cleaning.

Polishing concrete information, an overview of the basic methods used for polished concrete. Including how to information on the polishing process; machines, tools ...

However, grinding is not just a process used on flat exterior surfaces. Grinding is performed on a ... operation is performed in one step with the creep feed grinder.

Grinding and Polishing / 37 Fig. Automatic grinding and polishing machine Subroutine : Cleaning Ceramographic Mounts After each abrasive step, rinse each ...

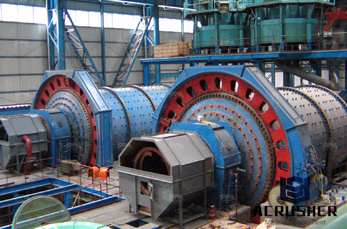

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

1. Cartridge inspection All inbound units are inspected and designated for remanufacturing or grinding. 2. Cartridges disassembled Endoflife units are disassembled.

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

How is concrete polished? ... this initial rough grinding is generally a three to fourstep process. The next steps involve fine grinding of the concrete surface ...

Wafer backgrinding is a semiconductor device fabrication step ... Prior to grinding, ... The wafers are also washed with deionized water throughout the process, ...

Basics of Grinding Fundamental Manufacturing Processes Video Series ... The Grinding Process Grinding is a material removal and surface generation process used to ...

Grinding (video gaming) Wikipedia, the free encyclopedia . Grinding is a term used in video gaming to describe the process of engaging in repetitive tasks during ...

WhatsApp)

WhatsApp)