WhatsApp)

WhatsApp)

Grinding Classification Circuits. ... If the case is a little reduces the critical speed to increase the ball mill level, ...

Sep 17, 2017· Feed Back. Rod mills, how they function Mine The Critical Speed is used for the determination of ball mill ideal operating speed. But for ...

Cement Kilns: Size Reduction and Grinding. Size Reduction and Grinding The Rosin Rammler Distribution (RRD) is applicable to materials that have been ground by a ...

/S"1 International Mining Congress and Exhibition of TurkeyIMCET 2003, (c 2003. ISBN The Effect of Fraction of Mill Critical Speed on Kinetic Breakage ...

critical speed calculation of ball mill_Ball Mill Critical Speed Calculation mill critical speed grinding critical speed ball mill ...

observerbased coal mill: Topics by Note: This page contains sample records for the topic observerbased coal mill from

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... The critical speed of the mill, ... Figure Effect of mill filling on power draft for ball mills.

ABSTRACT: In this study, the effect of fraction of mill critical speed was investigated on the limestone and the clinker samples using Göltaş cement factory ...

critical speed of ball mill – Ore equipment: ore crusher, ore . Ball mill critical speed, ball mill efficiency. What is the ball mill critical speed and how to ...

Ball Mill Critical Speed 911 Metallurgist. Mar 17, 2017, A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which, The critical speed of a ...

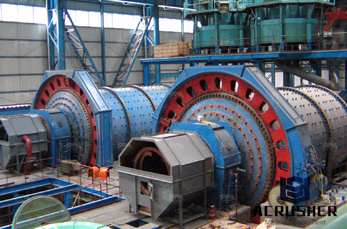

A ball mill is a type of grinder used to grind and blend materials for use in mineral ... Critical speed can be understood as that speed after which the ...

A cement mill (or finish mill in ... Ball mills are normally operated at around 75% of critical speed, so a mill with diameter 5 metres will turn at around 14 rpm.

Sep 20, 2017· Feed Back. Computer Wikipedia. A computer is a device that can be instructed to carry out arbitrary sequences of arithmetic or logical operations ...

https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill .

critical speed for ball mills BWZ Heavy Duty Apron Feeder BWZ series heavy duty apron feeder designed by SKT is one new type highefficiency.

How can you design of ball mill Answers. What is a ball mill and how does it function? Ball Mill is widely used in metal and nonmetal mines, building materials and ...

AMIT 135: Lesson 7 Ball Mills Circuits. Contents. ... after reaching a critical speed, the mill charge clings to the inside perimeter of the ... AMIT 135: Lesson 8 ...

critical speed in a ball mill BWZ Heavy Duty Apron Feeder BWZ series heavy duty apron feeder designed by SKT is one new type highefficiency.

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm.

Original document English (PDF 367kb) ,ABSTRACT: In this study, the effects of ball charge, powder filling, mill speed and while it asymptotically increased ...

critical speed of the ball mill. Ball Mills Mine This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently ...

Quick Easy Black Powder Ball Mill ... optimum material load, and optimum milling speed. ... The details and tricks which follow are critical to ballmilling success.

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

WhatsApp)

WhatsApp)